An ultrasonic flow meter is a form of flow meter that uses ultrasound to measure a fluid’s velocity and calculate its volume flow. By averaging the difference in transit times between ultrasound pulses propagating into and away from flow direction, or by assessing the frequency response from the Doppler effect, the meter can calculate the mean velocity along the route of an emitted ultrasound beam using ultrasonic transducers.Read More…

Sierra manufacturers high performance mass flow meters and controllers for nearly any gas, liquid or steam. Customers choose Sierra when they need an accurate and repeatable flow measurement, short delivery lead times, expert flow advice and long term support. When it matters, choose Sierra. Visit www.sierrainstruments.com.

AW-Lake Company manufactures flow monitoring equipment and goes to market through four brands: TRICOR Coriolis Technology, LAKE Monitors, AW Gear Meters and Turbine Flow. The broad range of flow meters include coriolis mass, positive displacement, variable area and turbine technologies. We service many industries, including oil & gas, automotive, food & beverage, chemical processing and...

At Niagara Meters, we specialize in providing high-quality flow meters and comprehensive solutions to meet the diverse needs of industries worldwide. With our dedication to excellence and extensive experience, we have established ourselves as a trusted leader in the field of flow measurement. Our product portfolio encompasses a wide range of flow meters meticulously engineered to deliver accurate ...

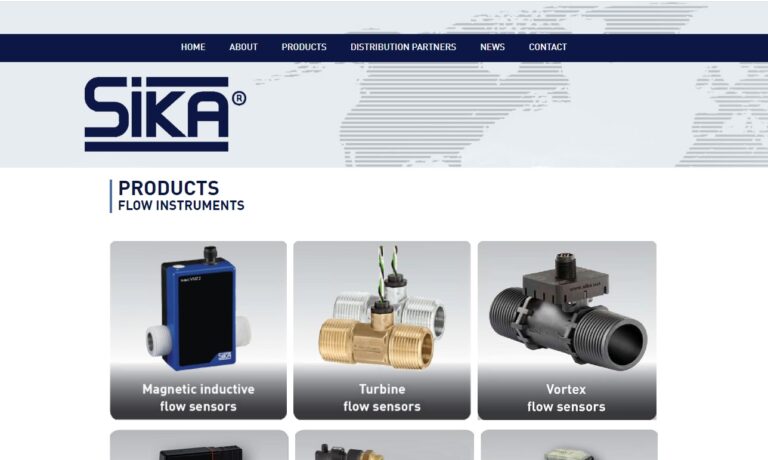

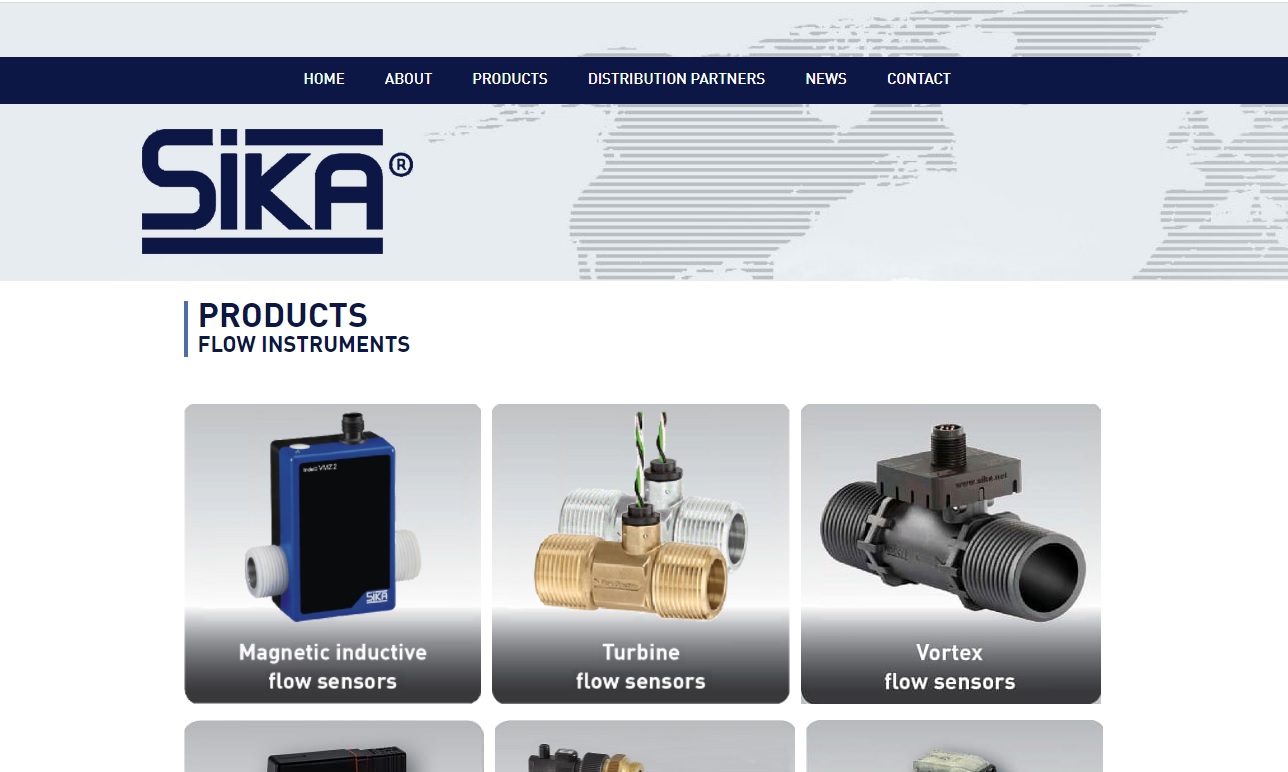

SIKA is a developer and manufacturer of flow control products and a wide variety of other measuring and monitoring systems. Our inventory includes flow sensors, flow meters, flow switches, and many more. We know that flow solutions aren't one-size-fits-all, which is why we provide consultation and flow management solutions that are individualized and customized to your requirements. When you...

Turbines is an ISO 9001:2000 certified manufacture specializing in the design of high quality, cost-efficient rugged turbine flow meters for industry oil and gas, and business flow measurement applications that require accuracy, repetition and reliability. We have established ourselves as a trusted leader in the field of flow measurement. We also offer a wide range of accessories such as...

More Ultrasonic Flow Meter Manufacturers

Principle of Operation

Unlike mechanical flow meters, which have moving parts, ultrasonic flow meters have no moving components and are only affected by the acoustic characteristics of the fluid. Depending on the specific flow meter, they may also be affected by temperature, density, viscosity, and suspended particles.

Ultrasonic flow meters employ sound vibrations at a frequency above human hearing. Wetted (insertion) transducers, which come into direct contact with the fluid, or external (clamp-on) transducers, which transmit the ultrasound via the pipe wall, are two ways to transmit this ultrasonic signal into a stream of moving liquid. Ultrasonic sensor transducers that serve as both an ultrasonic receiver and transmitter are typically used in transit-time liquid flow meters. By determining how long it takes for sound to move between both two transducers in both directions, the ultrasonic flow meter works by alternately emitting and collecting a discharge of ultrasound signal between the two transducers. The speed of the fluid in the pipe directly affects the variation of the transit time observed. The terms "transit time travel" and "Doppler shift" refer to two different categories of ultrasonic flow measurement techniques. The methods differ in terms of how the measurement is obtained with relation to direction. The time travel technique involves sending sound waves perpendicular to the flow and taking measurements in both directions. The Doppler technique involves projecting sound waves along the flow route and measuring the frequency of the reflected signal. The idea that there is a change in the speed of ultrasonic pulses when there is a change in the flow rate of a fluid is the basis of the theory underlying the operation of an ultrasonic flow meter.

Types of Ultrasonic Flow Meters

Dual and Single Clamp-On Ultrasonic Flow Meters

The least intrusive of the numerous flow meters is the clamp-on ultrasonic flow meter. They come in dual and singular forms and are fastened to the pipe’s exterior. The send and receive crystals are mounted within the same sensing body and clamped at a single location on the pipe surface in the single-sensor version. In the dual version, the receiver sensor and one sensor have separate bodies. This type of flow meter can only be used with specific types of pipe and cannot function with lined or insulated pipe, whether it is a dual or single version.

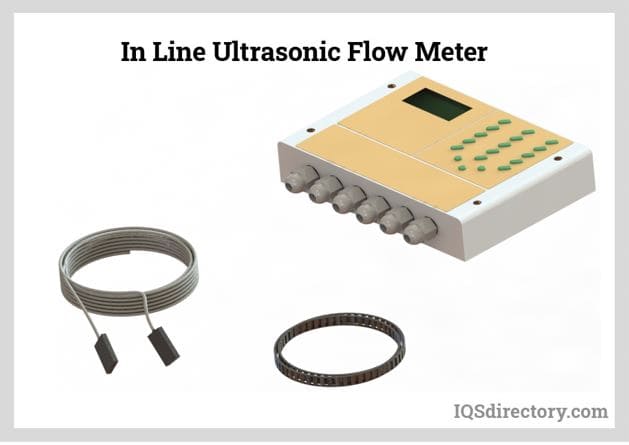

In-Line Ultrasonic Flow Meters

For flow rate measurement, in-line flow meters are put in the flow's course. Since they don't involve cutting the pipe, closing the operation, or adding delays to the process, these types of flow meters are frequently employed to measure flow rates. Ultrasonic flow meters provide a reasonably priced and practical measuring tool for in-line measurement systems since they may be employed right away. It just takes a few simple steps to utilize this type of flow meter:

- Configuring the pipe values into the screen

- Determining the transducer distance

- Clamping the transducers to the pipe

All of these steps may be completed while fluid is still in the pipe.

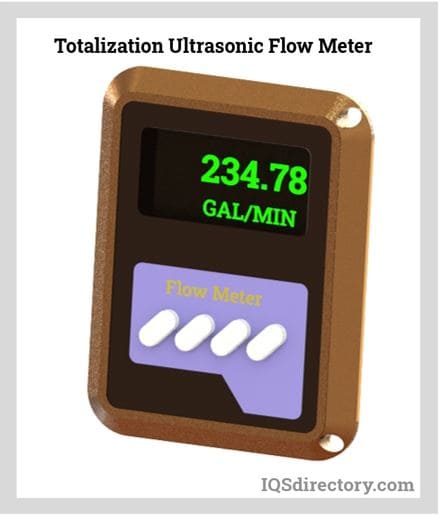

Totalization Ultrasonic Flow Meter

An ultrasonic flow meter with totalization offers a continual tally of the volume of fluid passing through a pipe. They are made to be used with pipes that have at least 100 ppm (parts per million) of suspended bubbles or particulate matter that is at least 100 microns (µm) in size. This type of flow meter is the best solution for the issue since particles or bubbles might cause the sound from standard ultrasonic flow meters to be deflected. The flow of sewage, waste activated sludge, reactivated sludge, slurries, lime slurries, crude oil, phosphates, and pulp stock can all be measured with totalization ultrasonic flow meters. Due to the bubbles and debris in the flow, the Doppler ultrasonic approach is utilized with totalization flow meters. The totalization ultrasonic flow meter comes in a range of designs.

Application of Ultrasonic Flow Meters

Due to its non-intrusive nature and use of sound to detect flow rates and volume, ultrasonic meters are frequently employed as commercial fluid flow monitoring equipment. The cost of employing the parts is reduced because there aren't any moving parts or inserting components that need to be repaired or replaced. Ultrasonic flow meters are used by any industry that needs reliable and exact information on the flow of fluids. Ultrasonic flow meters provide businesses with information on the availability and movement of fluids, from those for home use to those used in oil fields.

Choosing the Right Ultrasonic Flow Meter Supplier

For the most productive outcome when purchasing ultrasonic flow meters from an ultrasonic flow meter supplier, it is important to compare several companies using our directory of ultrasonic flow meter suppliers. Each ultrasonic flow meter supplier has a business profile page highlighting their areas of experience and expertise, and a contact form to directly communicate with the supplier for more information or request a quote. Review each ultrasonic flow meter business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ultrasonic flow meter companies with the same form.

Flow Gauges

Flow Gauges Flow Indicators

Flow Indicators Flow Meters

Flow Meters Flow Switches

Flow Switches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services